PACPROJECTPRO

PAC Project Professional Software Suite

Datasheet Download Link

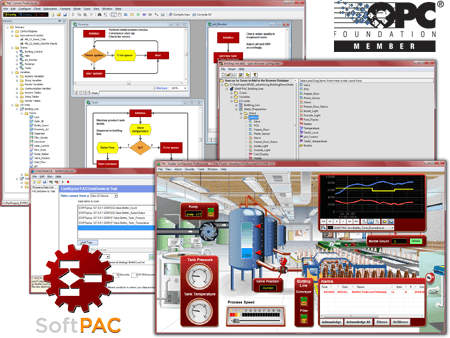

The PAC Project Software Suite from Opto 22 provides all the software you need for industrial automation, process control, building automation, remote monitoring, data acquisition, and Industrial Internet of Things (IIoT) applications in any field. One of four components of the SNAP PAC System, PAC Project software is fully integrated with SNAP PAC controllers, brains, and I/O, making it easy to understand, select, buy, and apply an automation system for your needs.

Easy to use and suitable for projects from simple equipment management to full industrial control, PAC Project Professional includes the following:

– PAC Control Professional, a full-featured, flowchart-based tool for developing control programs to run on SNAP PAC controllers

– PAC Display Professional, for creating human-machine interfaces (HMIs) for operators and technicians to monitor and interact with the SNAP PAC System

– PAC Manager, a utility program for configuring and maintaining SNAP PAC controllers, brains, and I/O

– OptoOPCServer, a fast and efficient server for communication with all OPC 2.0-compliant clients

– OptoDataLink, for sharing SNAP PAC System data with commonly used databases, including Microsoft(R) SQL Server, Microsoft Access, and MySQL

– SoftPAC, a software-based programmable automation controller (PAC) designed for PC-based control

About controller redundancy: PAC Project Professional 9.0 supports controller-level redundancy. Controller redundancy is distinct from network link redundancy, which has been supported for some time.

- – Network link redundancy provides a backup network connection in case the network should fail; it provides a second communication route for the controller.

- – Controller redundancy, in contrast, provides a backup controller that takes over running the strategy in the unlikely event that the first controller fails. In addition to PAC Project Pro 9.0, controller redundancy requires two identical S-series PACs and the SNAP PAC Redundancy Option Kit.

Developer and IIoT ready: Because Opto 22 SNAP PAC R-series and S-series controllers include an HTTP/HTTPS server and a RESTful API (application program interface based on the REST architecture), you can securely access I/O point and variable data in your PAC Control program using the language of your choice. Data is returned in JSON format. For complete information, see developer.opto22.com.

NOTE: If you do not need complex network architectures, redundant controllers, support for legacy Opto 22 FactoryFloor systems, OPC communication, or database connectivity, you may find that the free PAC Project Basic Software Suite provides everything you need.

Compare PAC Project Basic and PAC Project Professional.

Watch SNAP PAC System videos.

Watch Quick Tips videos.