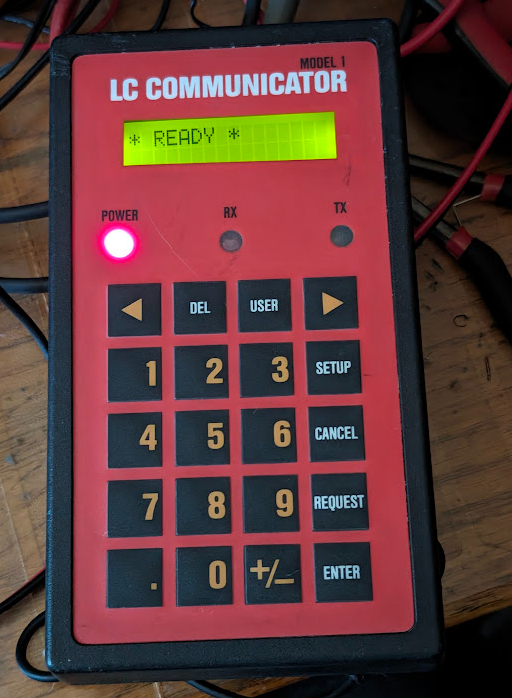

Learn about some of the changes and benefits of Node-RED 3.1.7 included with the recent groov EPIC 3.6 firmware release.

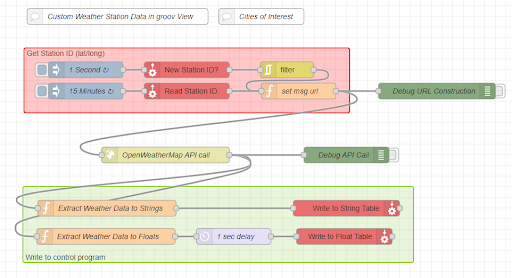

Node-RED 3.1.7 has many useful new features and quality-of-life improvements—mainly to the editor itself. A great example is that the flow tabs at the top of the editor now indicate when they contain a change that has not been deployed. This simple addition clarifies what will be restarted when you choose among deploying modified nodes, modified flows, or a full deploy.

Let’s talk about what other welcome additions you’ll find in Node-RED in the latest 3.6 firmware release of groov EPIC.