Industrial edge computing enables cutting-edge indoor agricultural control and business intelligence.

Indoor agriculture is more than just greenhouses now, and for good reason. As populations grow and food demand increases, supply chains become stressed. By moving agriculture indoors, food production can happen even in the middle of dense towns and cities where many food products are ultimately bound. And unlike Mother Nature, indoor environments can be controlled for consistent, efficient, year-round production.

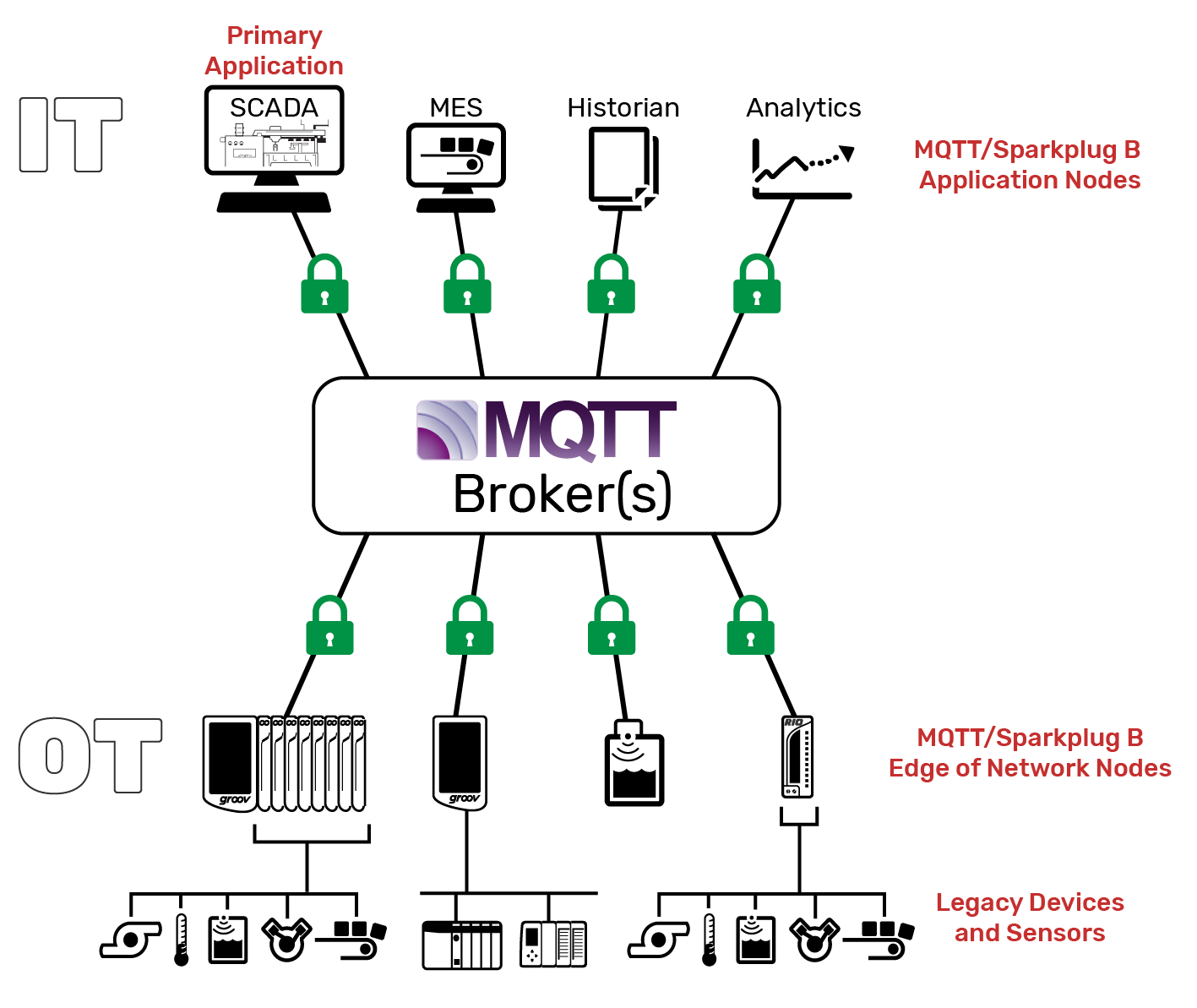

But as you know, not all automation is alike. Traditional control systems designed for large-scale environments aren’t well-suited to the skillset or budget of many small, indoor grow operations, but on the other hand, more affordable solutions lack centralized integration. Solutions big and small also fail to provide the security, storage, and communication features that could support useful data collection for developing business intelligence (BI).

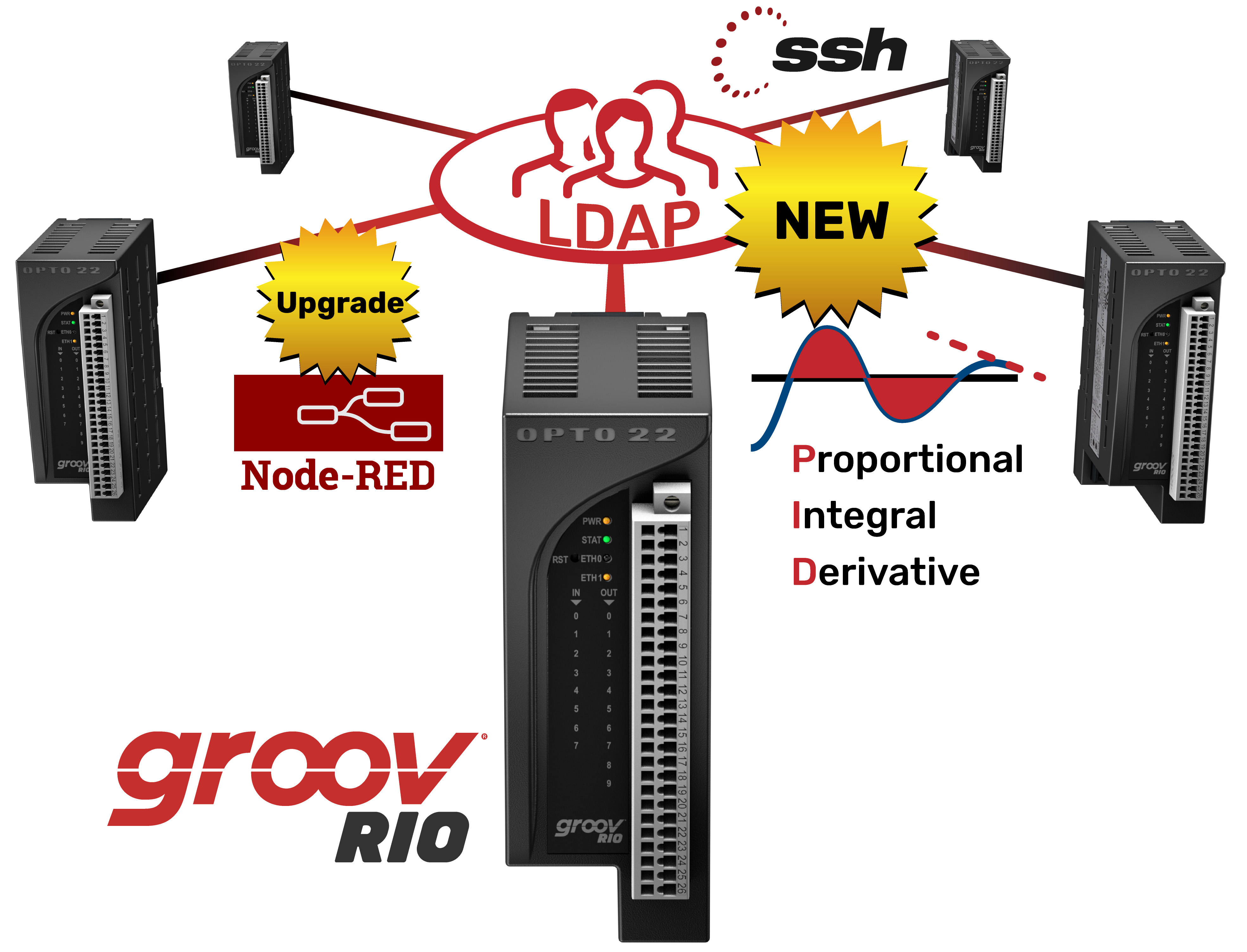

So when MicroClimates set out to design a scalable automation and BI solution to support the growing indoor ag industry, “we went out to look for the best of breed hardware to put our software onto and that’s why we ended up with groov RIO“, says Loren West, MicroClimates’s CTO.

Read More…