Asyril develops, produces and markets high performance robotic parts feeding systems for components from <0.1 up to 150mm in size. All Asycubes products are based on our innovative 3-Axis Vibration Technology which is compatible with 99% of all part geometries and materials.

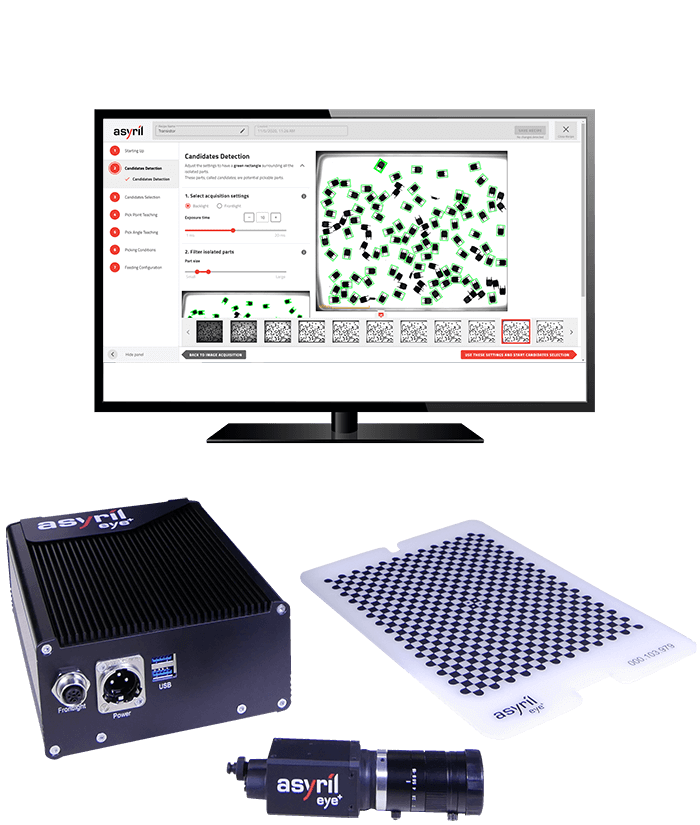

Asyril’s standardized feeding systems allow for minimal production changeover times, have demonstrated to function extremely reliably, all the while being highly compact thus saving valuable factory floor space. The systems are typically used together with an industrial vision system and an industrial robot, enabling a never before achieved level of flexibility for the digital factory of the future.

Asycube Advantages

- Compatible with all part geometries : 99% of parts can be fed on our feeders - including complex geometries and delicate materials

- Minimum production changeover times enable flexible, future-proof production systems

- Extremely gentle part handling due to 3-axis vibration technology : parts can be moved in all directions, including the optimal choice of flipping amplitude for each part. Minimal abrasion as parts do not need to be recirculated. Platform purge possible.

- Advanced reliability and durability due to State-of-the-Art Voice Coil Technology ; no compressed air

- Precise part detection thanks to integrated, adjustable backlight / optional EYE+ Smart Control Systems.

- Systematic part orientation can be achieved with intelligently structured platforms (grooves, holes, nests)

- Easy configuration with Asyril's Feeder Control Center Software

- Simple system integration thanks to numerous software plugins with the most popular robot brands.

- Simple Communication with all types of automation systems based on standard communication protocols TCP-IP,

- Preconfigured fieldbus gateway/hardware adapter available for